-

Someone Still Has to Make Robots!

Rock Valley College’s TechWorks Facility

As manufacturing companies throughout the U.S. are struggling to find skilled workers, there has been an increased urgency to find ways to get more people into the manufacturing sector of the economy. Manufacturing has continuously evolved since its inception to do things faster, better and more economical with technology being a driving factor and the increased use of robotics. That issue of unskilled workers is being addressed through an employer-driven training organization, TechWorks, that is offered through Rock Valley College. The program develops and delivers a customized curriculum to prepare students for a career in advanced manufacturing in just six to eight weeks. TechWorks initially started out with 72 hours of training that consisted of setting up and operating CNC machine tools, and has evolved to now include 150 hours of training.

Rj Link International has been helping to support the TechWorks program by keeping in close contact with TechWorks Training Specialist, Gordy Blaisdell, and by offering tours for the students. Employees from Rj Link Int. recently visited with Gordy at the TechWorks facility to talk about the program and the advantages of having students visit a manufacturing facility. Gordy stated “A manufacturing company is not always a dark, dingy place that people think it is, but a place where there’s a lot of activity going on with people making decisions. Seeing what the equipment actually looks like in a production environment is very beneficial to the students, so they can get a feel for it all.” Gordy further stated “Manufacturing having been painted as a gloomy picture, a place where you wouldn’t want to work over the years, is just not the case with the new technology, and the new machines that are out there. It’s really a very challenging and an exciting career that pays a lot of money if you learn the correct skills. If we don’t train workers, then the other solution is that parts will be made somewhere else. Why not make them here and build our economy. The schools need to realize that not everyone fits the mold for a four year degree. There are so many technical jobs available, and the technical skills are where the jobs are in the future.”

As technology continues to be a driving factor in taking manufacturing to a level that we have never imagined, the need for skilled workers will continue . Gordy stated “What the changes in technology means for workers is that they need to have higher skill sets. The higher skills will make the employee worth more, and will increase their take home pay. Someone still has to make the robots.” Gordy commented further “We’re very fortunate to have companies like Rj Link allow us to tour their facilities. It has been extremely beneficial to our program.” Rj Link Int. understands the importance of being involved with the local high schools and the TechWorks program. As skilled baby boomers retire, the urgent need to have more companies involved with helping to draw people to manufacturing is one that cannot be overlooked.

Learn More: TechWorks

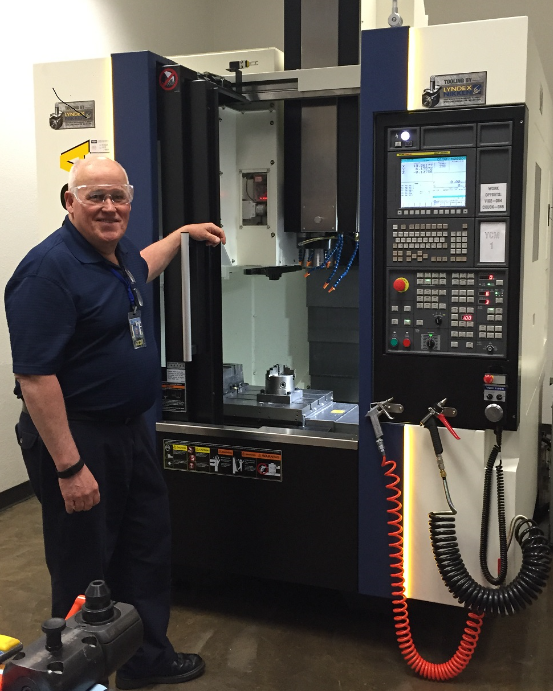

- TechWorks Shop Tools

- TechWorks Training Specialist – Gordy Blaisdell

1-815-874-8110

1-815-874-8110