Gearbox solutions for the Food Industry

Food processing equipment often faces high shock loads, tight space constraints, and strict sanitation requirements. RJ Link designs custom gearbox solutions for demanding food-industry applications where reliability, uptime, and washdown compliance are critical.

When repeated failures become “normal,” we help teams redesign the drivetrain component that’s actually taking the abuse.

Review the Case Study below to learn more about how we’ve applied our Gearbox Technology to the Food Industry

Case Study

Broken Gearbox Replacement for High-Shock Dough Processing

Customer: Local Food Manufacturer

Project Overview

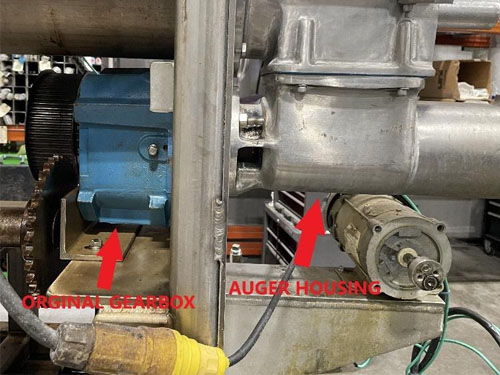

A snack food manufacturer was experiencing repeated gearbox failures on a dough batching system. In production, large dough balls were forced through an auger into a die press, generating extreme and inconsistent shock loads that were transmitted directly into the gearbox.

The Challenge

- Gearbox life ranged from a few months to one year, causing unpredictable downtime.

- Failure inconsistency made preventative maintenance difficult to implement.

- Any new design had to fit existing space constraints and exceed sanitation/washdown requirements.

Rj Link International Inc was contacted to see if a solution could be found. A new gearbox design needed to be able to handle the extensive shock loading, fit within the tight physical size limitations, and exceed sanitation/wash down requirements.

Observed Failure Modes

As shown here, our inspection revealed consistent damage patterns typical of excessive axial load and heat:

- Heat discoloration on the shaft

- Destroyed roller bearings due to axial load

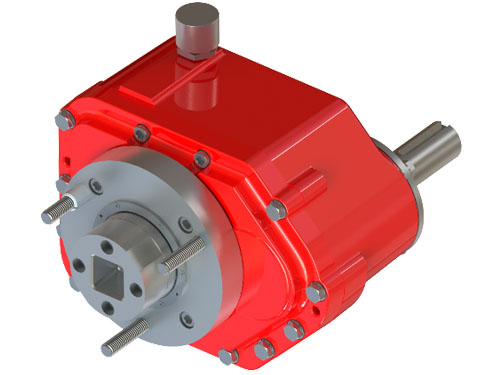

the RJ Link Solution

RJ Link engineered a new gearbox design to handle extensive shock loading while meeting the application’s tight dimensional envelope and sanitation demands.

The first prototype gearbox was installed Oct. 2022. Within two years, the only maintenance the gearbox has required is an oil change due to hours of operation. With the proven performance of the Rj Link gearbox, the customer is now changing all of their dough batching machines over to the Rj Link gearbox. The customer is extremely happy with how robust the gearbox is, and how much it has improved their machine up-time.

Results

- Prototype installed: October 2022

- Maintenance over two years: Oil change only

- Outcome: The customer is extremely happy and is now changing all of their dough batching machines over to the Rj Link gearbox.