-

Creep Drive Design

- Creep Drive Design

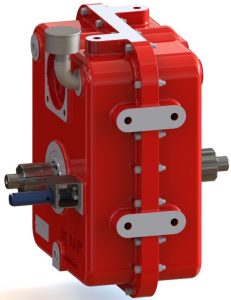

Rj Link’s new drive design is being used for Creep Drive in conjunction with regular operation drive applications. In this design we used universal mounting tabs allowing the gearbox to be installed in various orientations. All the customer needs to do is get it in the main-drive line, somewhat close to the transmission. How it works is quite simple, there are two distinct operating conditions. One being regular vehicle drive (operator), and the other being under-load (creep mode) precision speed & directional (operating) control.

When the Drive is engaged (Creep-Mode), the main vehicle transmission is shifted into neutral. Then a secondary motor (usually hydrostatic) is connected to the input shaft. This is what we call “Creep Mode”, and this allows the operator to have more precision operating direction and speed control. To shift back to standard operating mode, all the operator has to do is shift back to the main drive/transmission line connection.

Some of the benefits in specifying a Creep Drive Application:

- Ability to gain precise vehicle speed in both the forward and reverse operating directions.

- The life of the main drive line transmission is extended.

Some examples of markets that Creep Drive type gearboxes are used in include:

- Construction/mining

- Municipal

- Forestry

- Rail

- Other markets with remote access

1-815-874-8110

1-815-874-8110