-

Retrofit Gearboxes with Improved Performance Characteristics

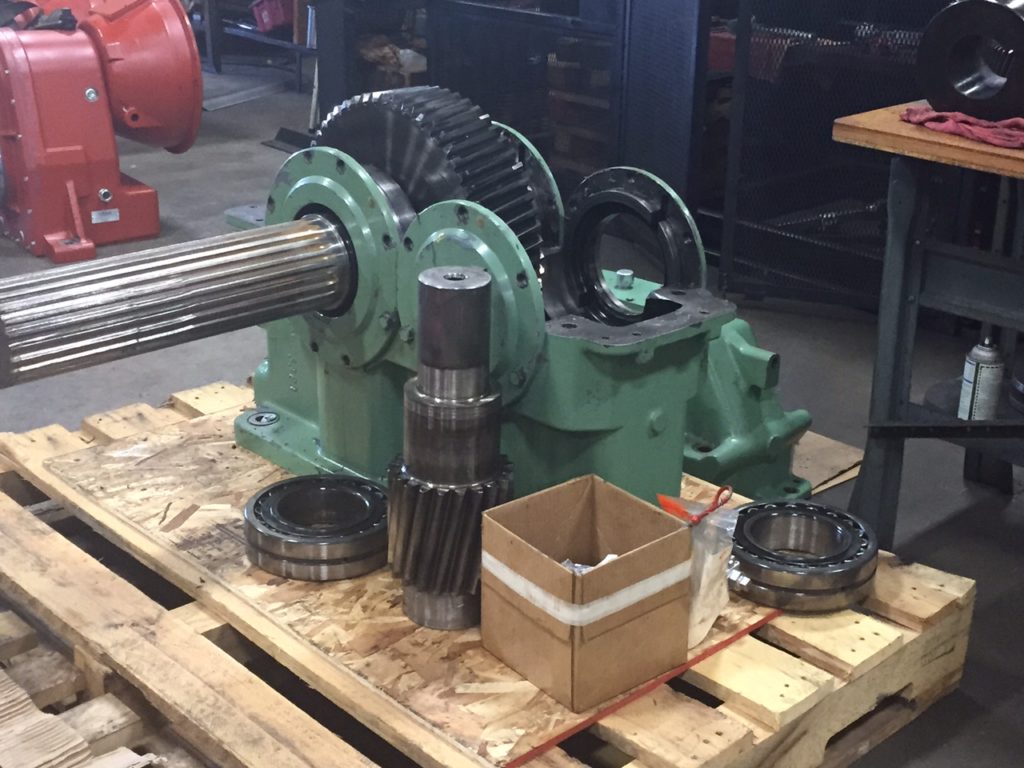

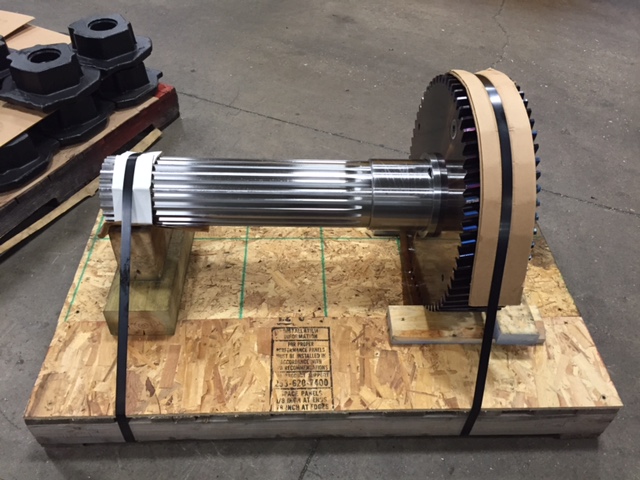

Gearbox Retrofitting

Rj Link Int. often sees requests come in for retrofit units from companies that are needing service components when designs are no longer available. Some issues that might need to be addressed are leak and/or vibration issues, or there could be a need to increase speed and/or torque. The footprint is important, as the input and output will still have to connect in the same place. Companies are looking for a retrofit gearbox solution that will fit in the same spot, and one that will be lighter weight with an extended life and better efficiency. Finding a solution to an existing package is often a more appealing option than to make changes on existing equipment.

Some Retrofit considerations:

- Cost justification

- Gained efficiency

- Operating characteristics

- Modifications to extend life of equipment

Retrofit Story:

A customer was having noise and leakage issues with their gearbox. Rj Link’s engineering team needed to find a retrofit solution to address those issues, as well as one that could not only be used on this customer’s existing equipment, but in future generations of the equipment as well. The enhancements that Rj Link’s engineering team offered with the retrofit unit solved the noise and leakage issues, and has extended the life of the customer’s equipment. This has resulted in an extremely happy customer, and the Rj Link team working with the customer to look at solutions to other aspects of their systems.

1-815-874-8110

1-815-874-8110