-

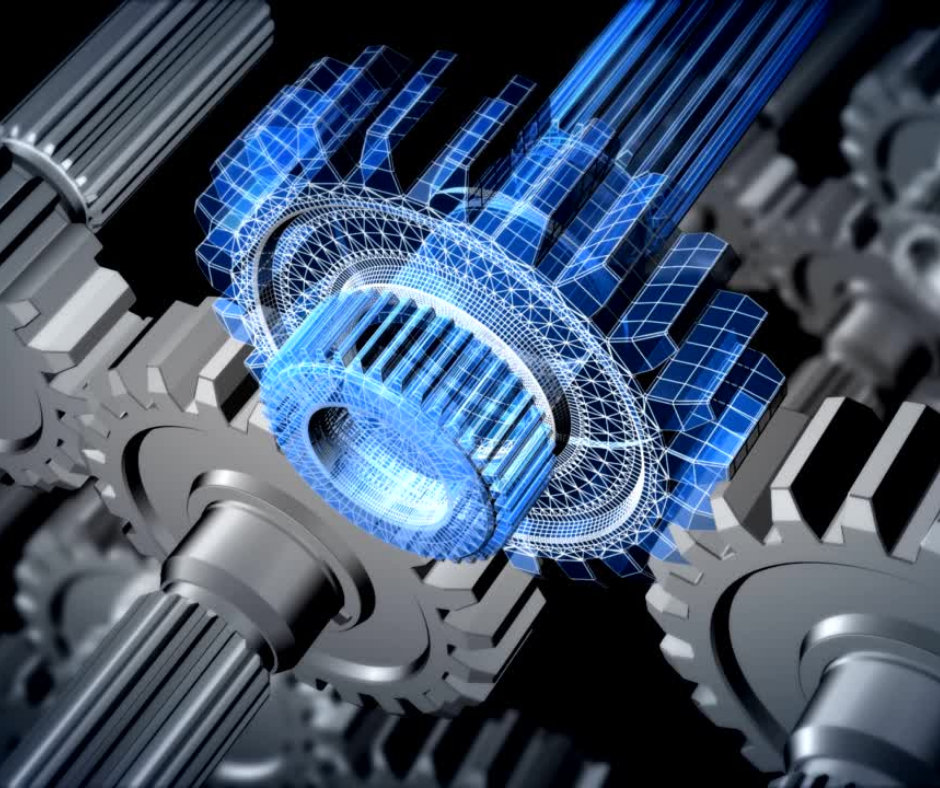

Single Piece to Volume Precision Machining

Rj Link’s manufacturing capabilities range from single piece prototype development to volume precision machining. We manufacture components and assemblies from a variety of raw materials including bar stock, plate stock, forgings and castings. We work with a variety of customer supplied materials including proprietary castings, specialty tubing and unique forgings. We can also provide additional services such as EDI, inspection, bar coding and more.

More detailed list of In-House Capabilities:

- Vertical CNC Machining Centers: Max. 59” length, 31.5” width, 23” height

- Horizontal CNC Machining Center: 25” cube size: U

- CNC Turning: Max. 24” dia., max. 56” length

- Broaching: 50 ton & 5 ton, Key min. 125″ and max 1″, Spline dia min .75″ and max 3.855″

- Hobbing: 33.5” dia., 2.5 DP, stock SAE & metric hobs

- CNC Crown Hobbing: 14” dia., 4 DP

- Shaping: 36” dia., 6” max. gear face, 3.5 DP

- Gear Shaving: 1” thru 12” dia., 4 thru 16 DP, Crown Shaving

- Tooth Pointing/Tooth Rounding: Up to 16” diameter

- Gear Grinding: Up to 15.74″ diameter. AGMA class 5 per AGMA 2015 inspection standard. Previously AGMA class 12 per AGMA 2000-A88 standard.

- Assembly & Test Capabilities

LEARN MORE

1-815-874-8110

1-815-874-8110