-

Using a Speed Reducer as a Speed Increaser

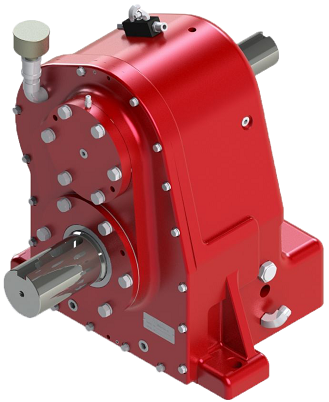

Specialized Gearbox

Speed reducers are widely available in a multitude of ratios and power ratings. Under some limited conditions, speed increasers can also be used as speed reducers. Some types of reducers cannot be used as increasers. Many worm gear reducers and some cycloidal designs will not back drive as an increaser. In the more common case of the worm reducer, if the lead angle of the worm is less than 10 degrees, the gear set is self-locking. In this case, the frictional forces in the gear mesh cannot be overcome by a torque applied to the worm wheel.

Spur and helical gear reducers are the best candidates for use as a speed increaser. Generally a helical or spur gear speed reducer may be used as a speed increaser within the same speed. For example, a 4:1 ratio helical gear speed reducer rated at 5HP, & 1750 RPM input, can be used as a 1:4 ratio helical gear speed increaser rated at 5 HP, 438 RPM input. In this case, the resulting gear, bearing loads and shaft speeds are the same in both applications. This case is often not very helpful.

Why Can’t the 5HP Reducer be Used as a 20HP, 1750 RPM increaser?

- The torque loading across the unit is the same as the reducer, 720.3 lbf-in on the low speed shaft and 180 lbf-in on the high speed shaft.

- Torque kills speed reducers, speed kills speed increasers

- At 1750 RPM input, the output speed is 7000 RPM

- The higher speed operates the gears, bearings, lubrication and seals beyond their design range

Gear tooth loading is affected by speed, the higher pitch line speeds in the speed increaser will derate the gear capacity in a non-linear relation to shaft speed. The unit has less load capacity. Even at reduced load (5HP, 1750 RPM input), depending upon the accuracy of the gearing, the dynamic load affect may be nearly equal to the load reduction.

Bearing Life Directly Impacted by Speed:

- A ball bearing operating within its speed limit will have its life reduced by a factor equal to the ratio of the speeds

- If the bearing is operating beyond its speed limit, the life reduction can be significantly greater

- The output shaft speed of 7000 RPM will likely take the bearings beyond their speed limit

- Reducing load can have an offsetting effect on bearing life

Lubrication is Dramatically Impacted by Speed:

- High speeds can result in churning losses in oil lubricated gearboxes where the oil type and fill level have been determined based upon the requirements of a low speed gear reducer

- The churning losses may exceed the capability of the unit to dissipate the heat loading to reduced gear and bearing life, and possible thermal runaway

- Oil temperature is related to oil viscosity, the key factor in the lubricating ability of the oil

- Higher oil temperature means lower viscosity, thus reduced gear and bearing load capacity

- Greased lubricated gears and bearings have more limited load and speed capability, thus lower capacity and life than oil lubricated components

- Churning losses are not affected by load reduction, they are speed driven

- The gear reducer has a limited ability to dissipate these additional thermal loads

Lip Type Oil Seals Rated Based Upon Shaft Surface Speeds:

- For any given oil seal installation, as the shaft surface speed increases, the life of the oil seal is reduced

- A four to one increase in shaft surface speed is significant, leading to a significant reduction in seal life

- The head generated by the rubbing action of the lip seal on the shaft is directly related to shaft speed

- An increase in shaft speed creates a corresponding increase in seal loss, which adds to the heating of the lubricating oil, & adding to the thermal degradation noted above

In summary, helical and spur gear reducers generally may be used as speed increasers within the operating range for which they were designed as a reducer. Operating a gear reducer at a higher speed as a speed increaser will lead to significantly reduced load capacity and life, even at significantly reduced loads. Catastrophic failure due to thermal runaway is possible since lubricant churning losses and seal losses are speed dependent and not reduced with load. The gear reducer has a limited ability to dissipate these increased thermal loads.

1-815-874-8110

1-815-874-8110