-

Considerations with Gearing Components

Gearing Components

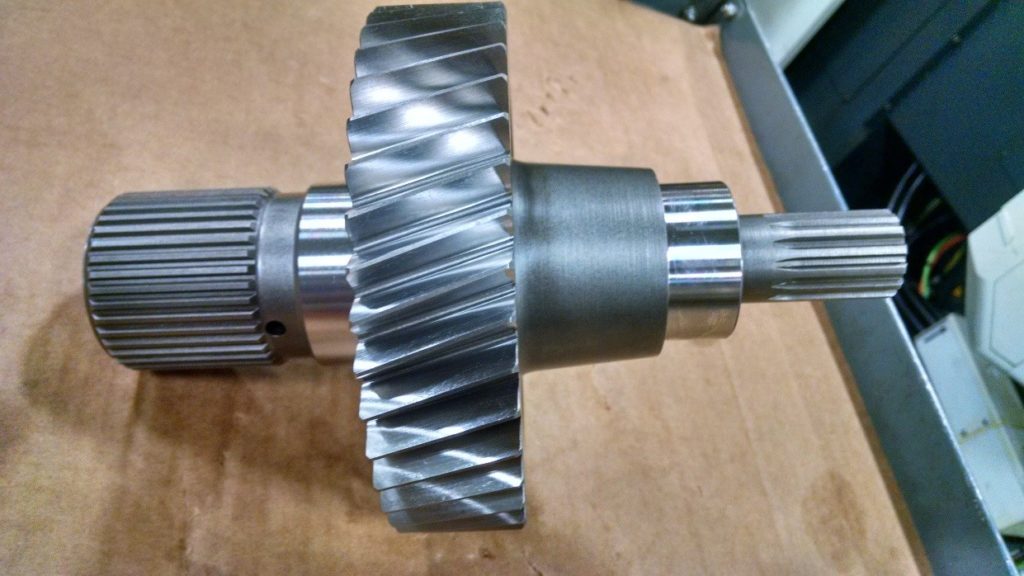

In addition to providing custom designed, manufactured, assembled and tested gearboxes, Rj Link’s specialty also includes a comprehensive mix of precision machining and gear hobbing, shaping and grinding capabilities. When requests come in for gearing components, understanding the application helps the Rj Link team to define what type of gearing will be needed.

Considerations:

- Machine Capability – Selecting a machine that is best suited for material & lead time, while producing a quality gear

- Quantity needed

- Size of gear or component

- Material Availability – Some materials lend themselves better for certain applications versus others. Special specifications can make it challenging to find quickly

- Heat Treat process – Looking at materials that lend themselves to certain processes such as nitrating process, carburizing process, etc.

- Improved life

- Repeatability

- Cost effective alternative

The quality of gearing you want, quantity, size and the need date are variables that will help us to determine how we pursue your project and meet the defined requirements. Rj Link is able to improve durability and endurance with grinding capabilities to allow for higher quality gears. If you need rugged gears, we can use shot peening as an option. Rj Link is able to make recommendations based off of your system, components and can offer new and redesigned products as a drop in replacement.

1-815-874-8110

1-815-874-8110